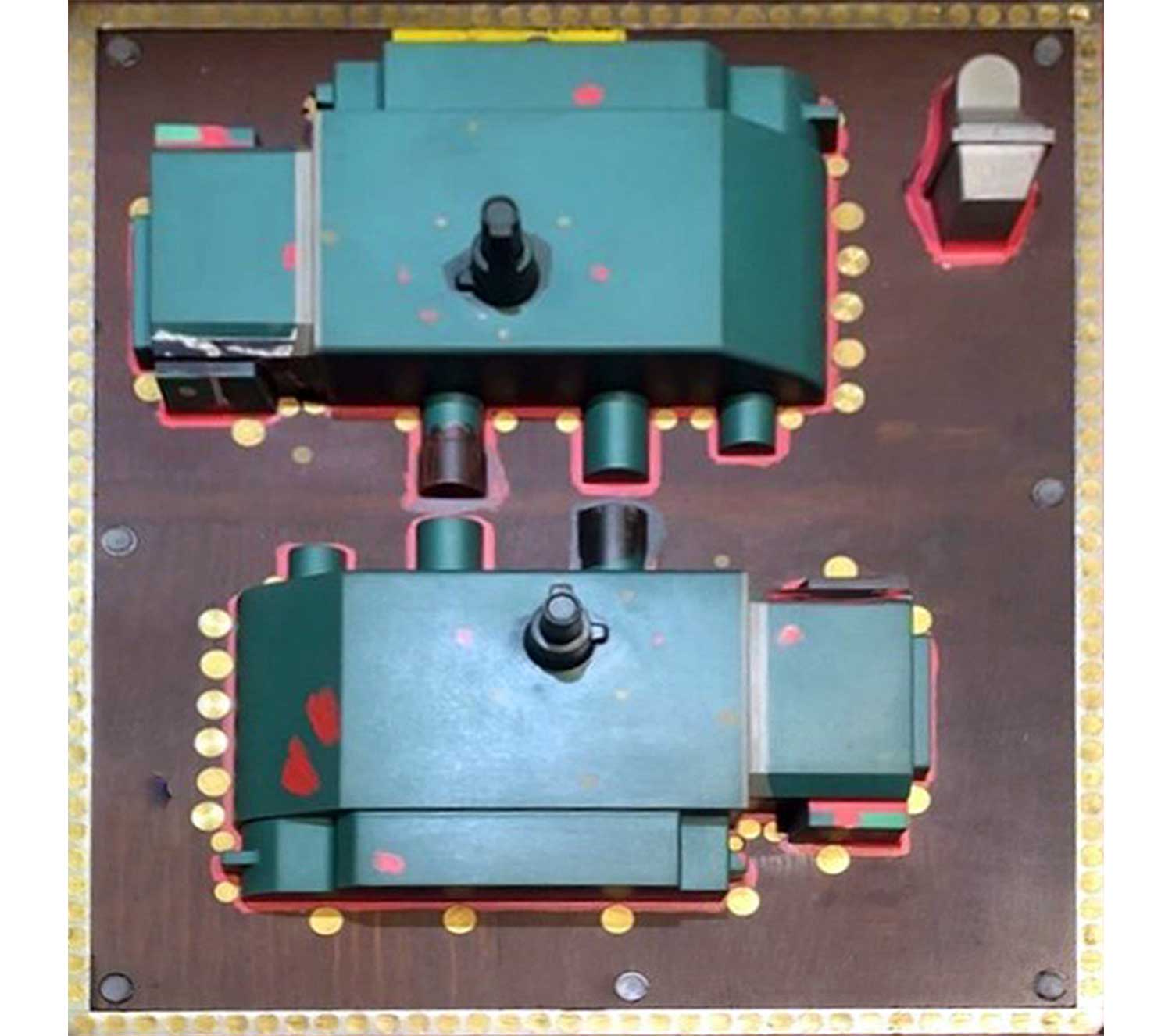

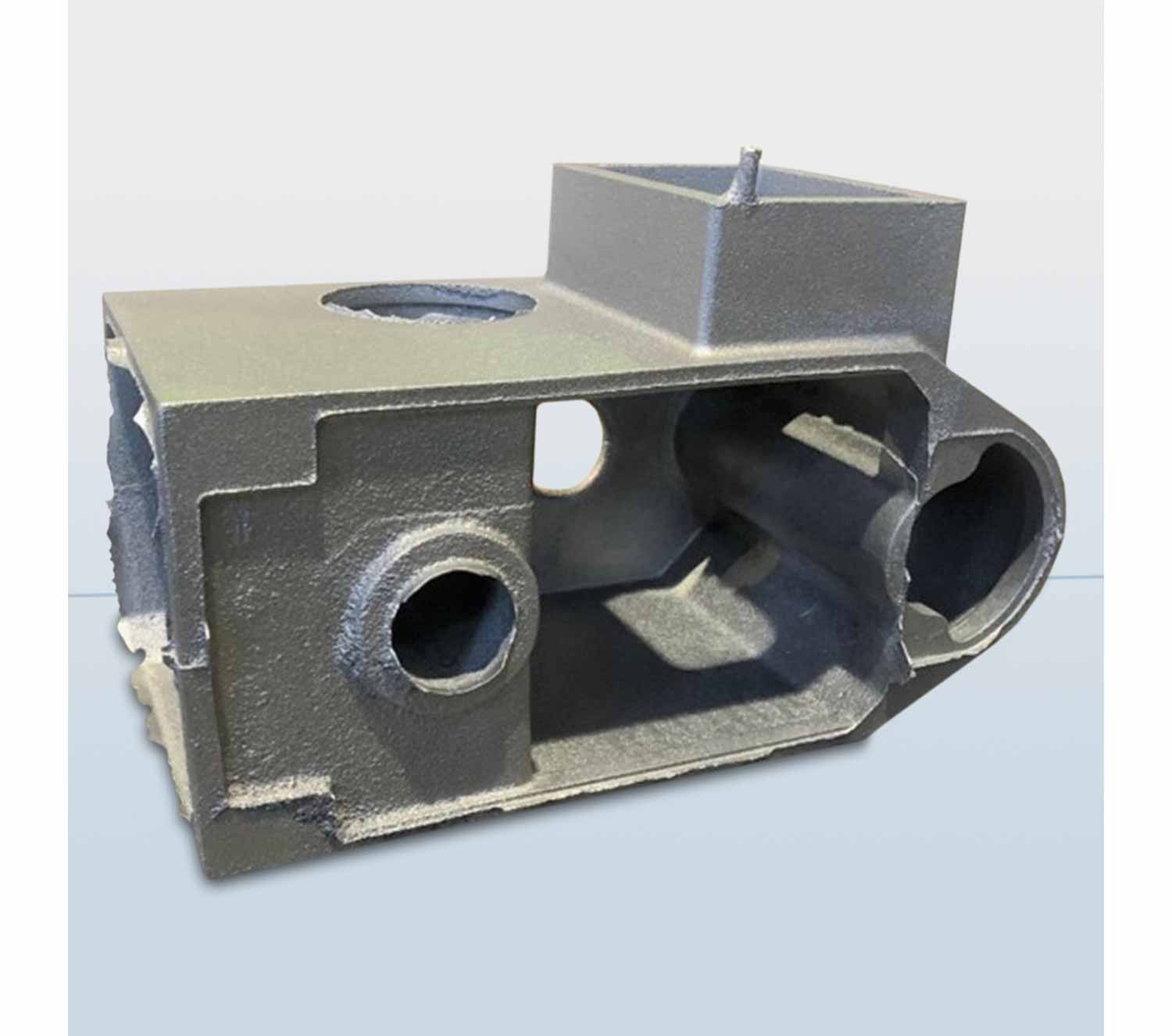

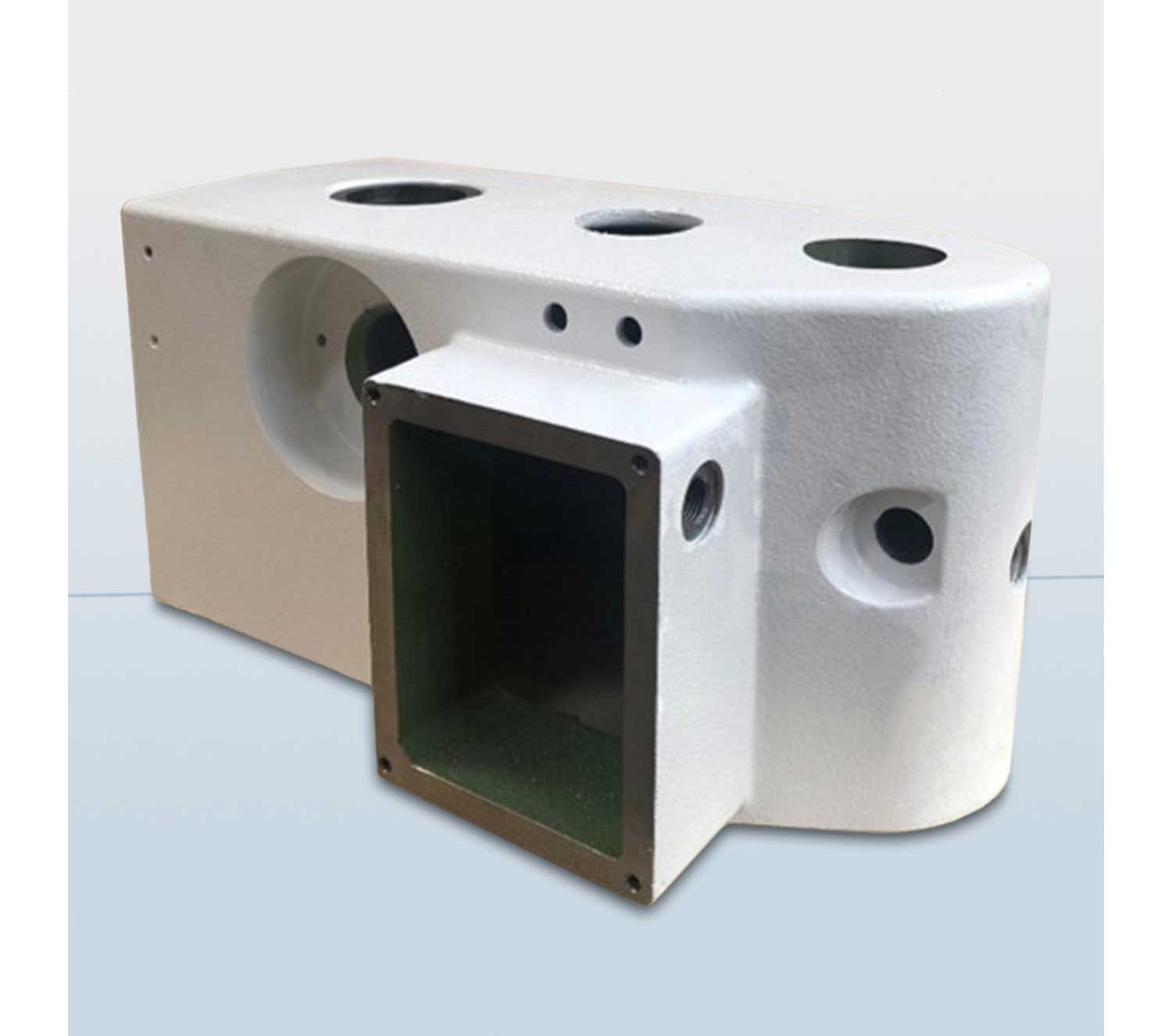

FOUNDRY

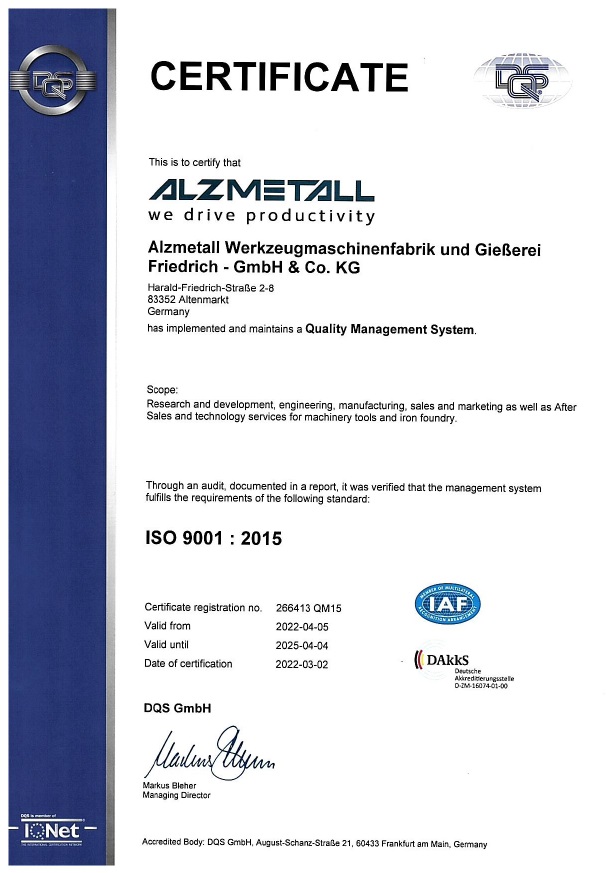

We want to become your first-class business partner in terms of Total Cost. In doing so, we offer you the shortest possible delivery times while maintaining highest quality standards, as we are having ample capacities to offer castings, machining and subassembly from one single source.

Our competence and experience not only in the field of foundry but also in the field of mechanical machine tools engineering offers you a full service package.

Challenge us!