GS 800

HIGHLIGHTS

- ALZMETALL-Gantry-Concept (AGK)

- Grey Cast Iron and Spheroidal Graphite Cast Iron

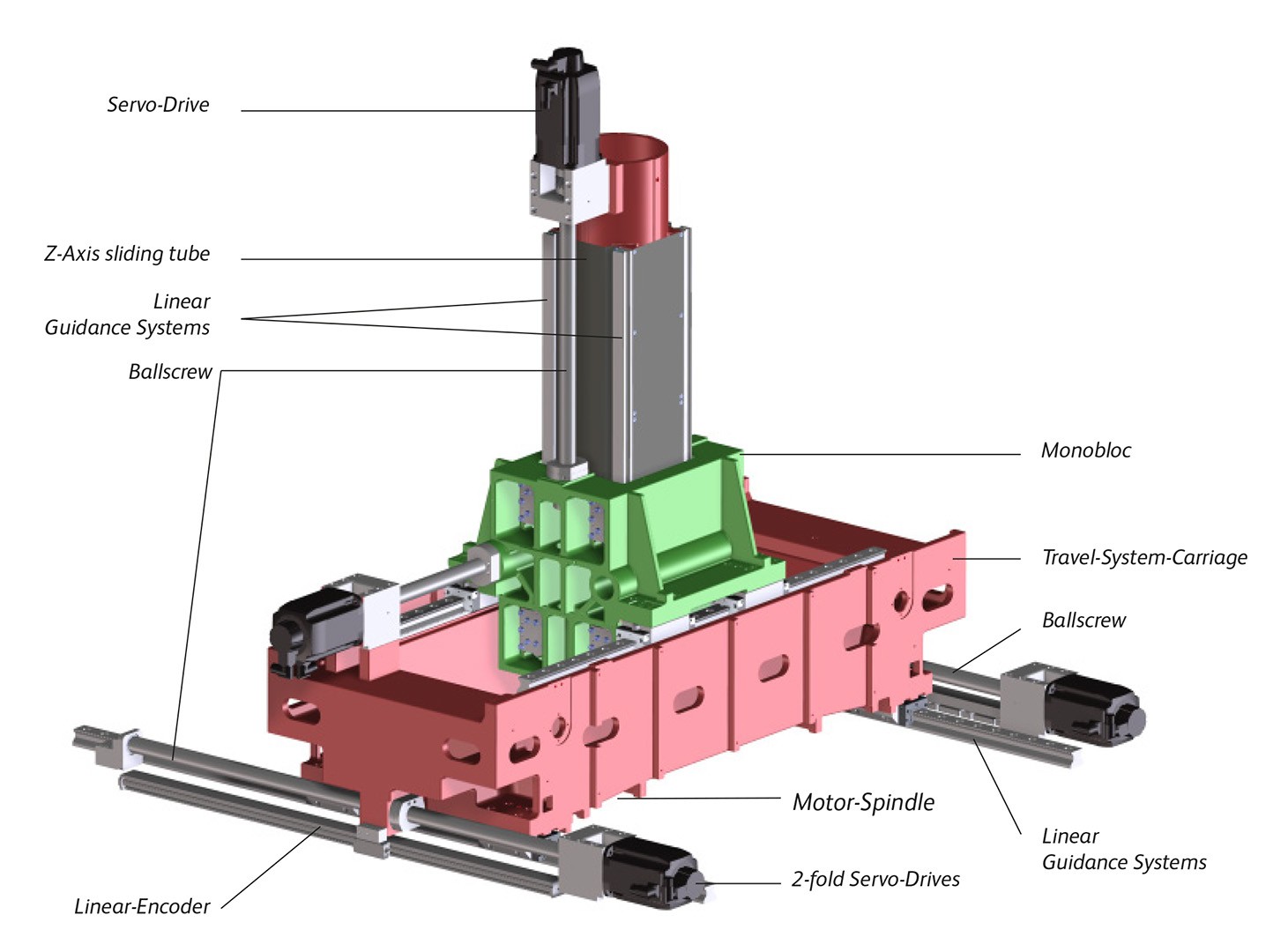

- Monobloc Travel-System-Carriage with incorporated Boxin-Box-System

- 2-fold Linear Guidance for X-Y-Travel System-Carriage and 4-fold Linear Guidance for Z-Axis with Travel-System-Carriage with integrated Motor-Spindle

- 3-fold Torque-Drives for Swivel-Axis (A-Axis) and Rotary-Axis (C-Axis) at GS 800NE/5-T and GS 800NE/5-FDT

- Hybrid-Machining-Applications such as: Drilling/Milling/Turning and Grinding at one Clamping-Set-Up

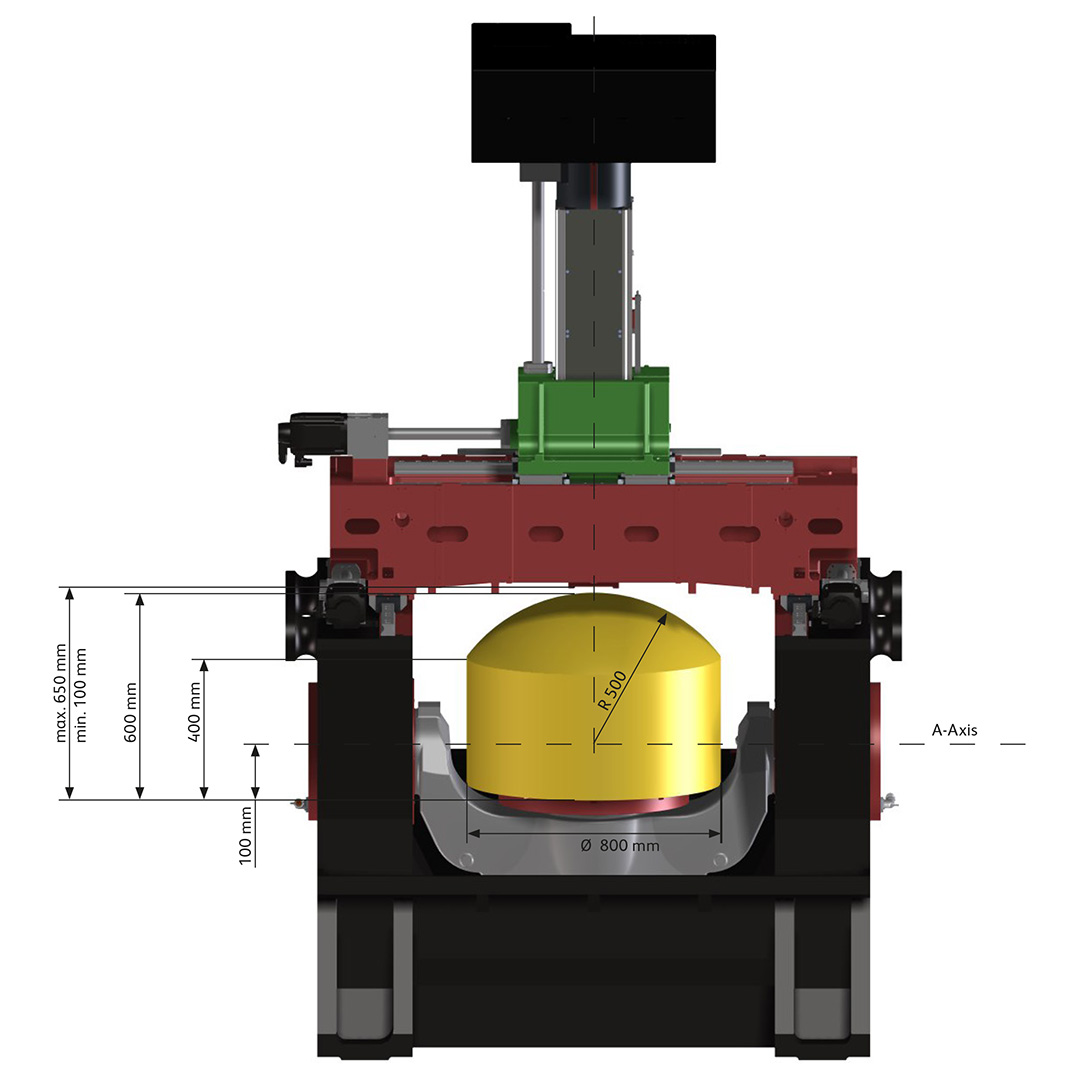

- Up to 1250 kg workpiece weight including Clamping-Set-Up-Device at GS 800/3

- Up to 500 kg workpiece weight including Clamping-Set-Up-Device at GS 800/5-T and GS 800/5-FDT

- Path taken X/Y/Z-Axis: 660 / 800 / 550 mm

TYPES

FOKUS ON OPERATORS NEEDS

- Access to Machine-Table ergonomically configured at working height

- Workpiece loading by front side, top side and sideways access.

- Mist extraction directly at Machine-Table

- Steeply sloping chip tunnel straight below Machine-Table

- Working-Space flushing with coolant [Option]

- Automatic Access-Door feature open/close [Option]

- Access to all maintenance units at working height

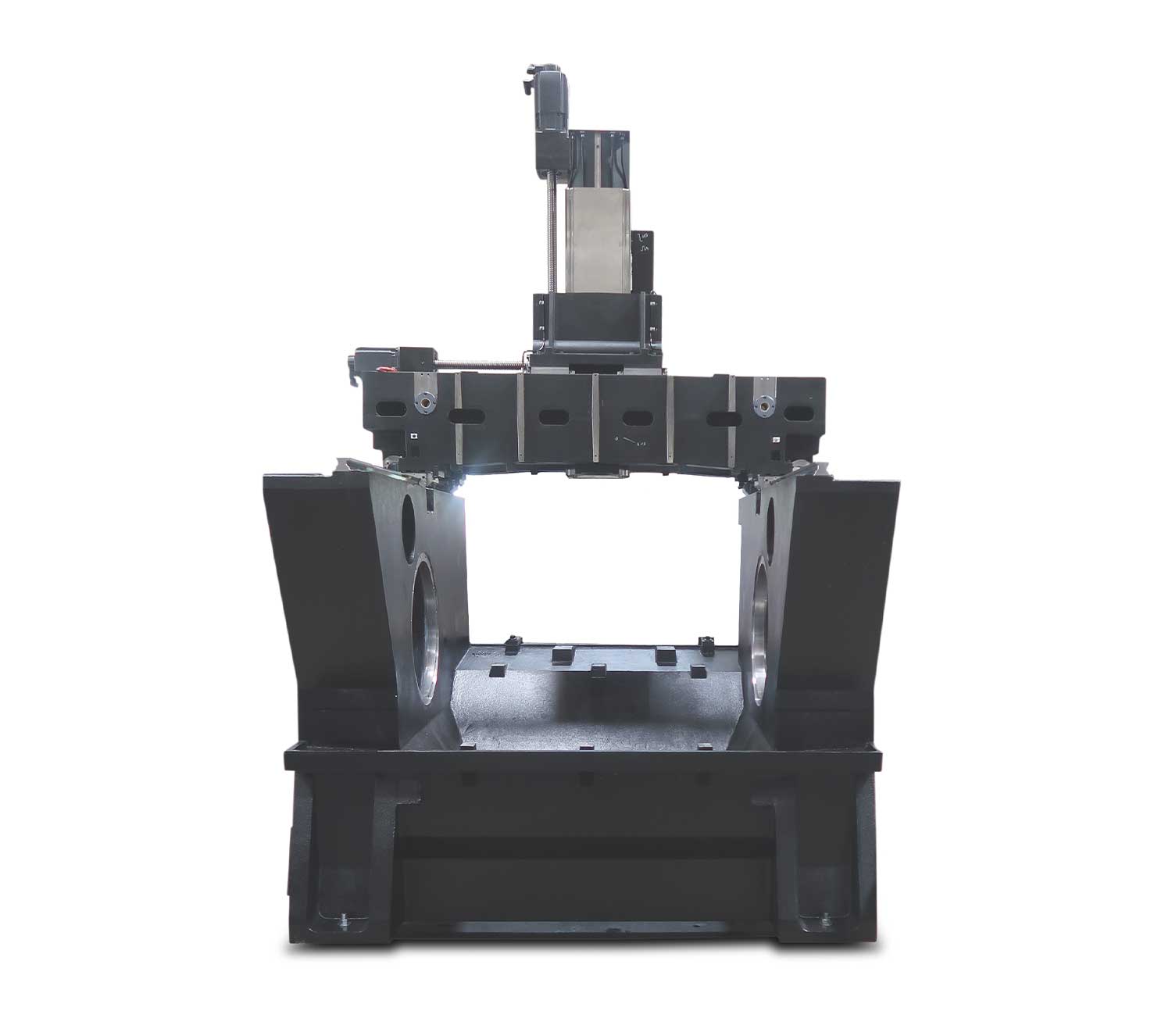

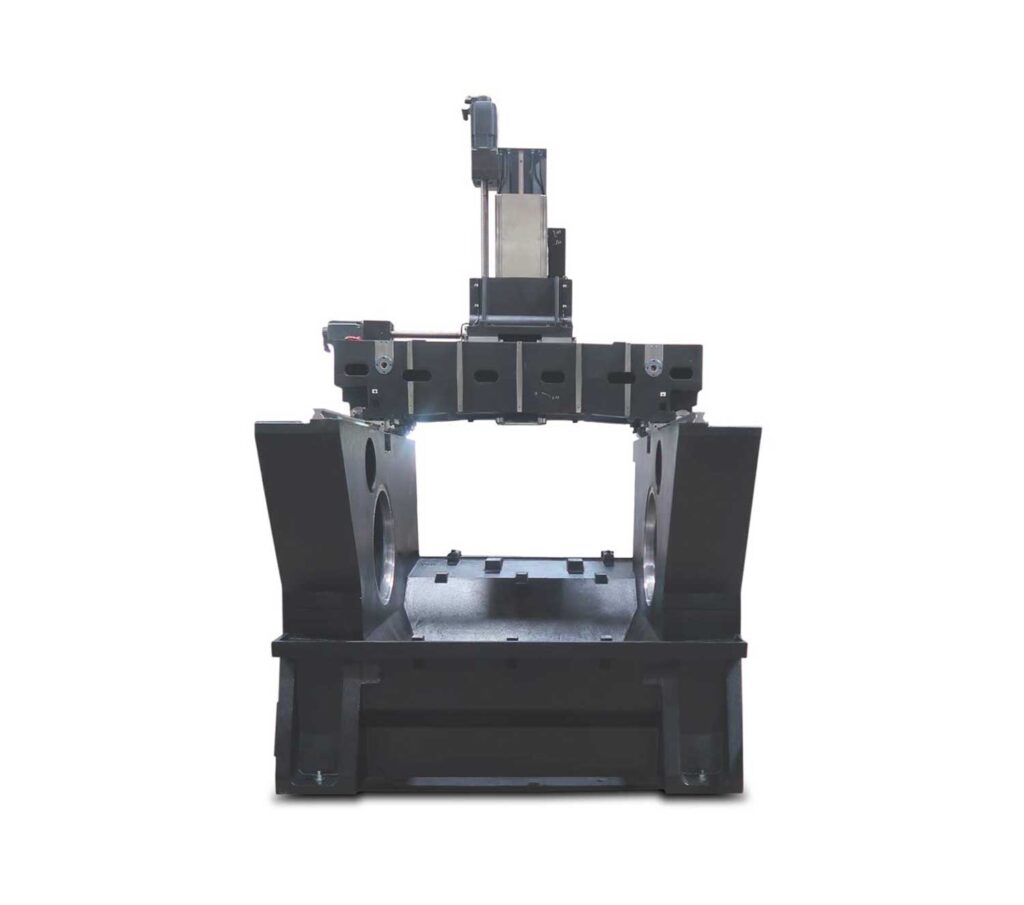

BASIC DESIGN

Rigidity, Dynamic and Thermal Symmetry

„that‘s it what counts“

Extreme rigid, Integral-Basic-Body prepared for:

- Monobloc Travel-System-Carriage for X-Y-Z Axes

- NC – Swivel- and Rotary-Table (A- and C- Axis) or Static-Table

- Disc-Tool-Magazine with 40 Tool Positions, alternative twin Disc-Tool-Magazine with [76] Tool-Positions. [Option]

- Rack-Type Tool-Magazine for [224] Tool Positions [Option].

All statically stressed Basic-Machine-Parts made from gray cast iron and all dynamically stressed Basic-Machine-Parts and components made from spheroidal cast iron.

GALLERY

PRODUCT CATALOG

Find out more about our machining centers by downloading our product catalogue.

Download PDF