| Y-Axis | |

|---|---|

| Z-Axis | |

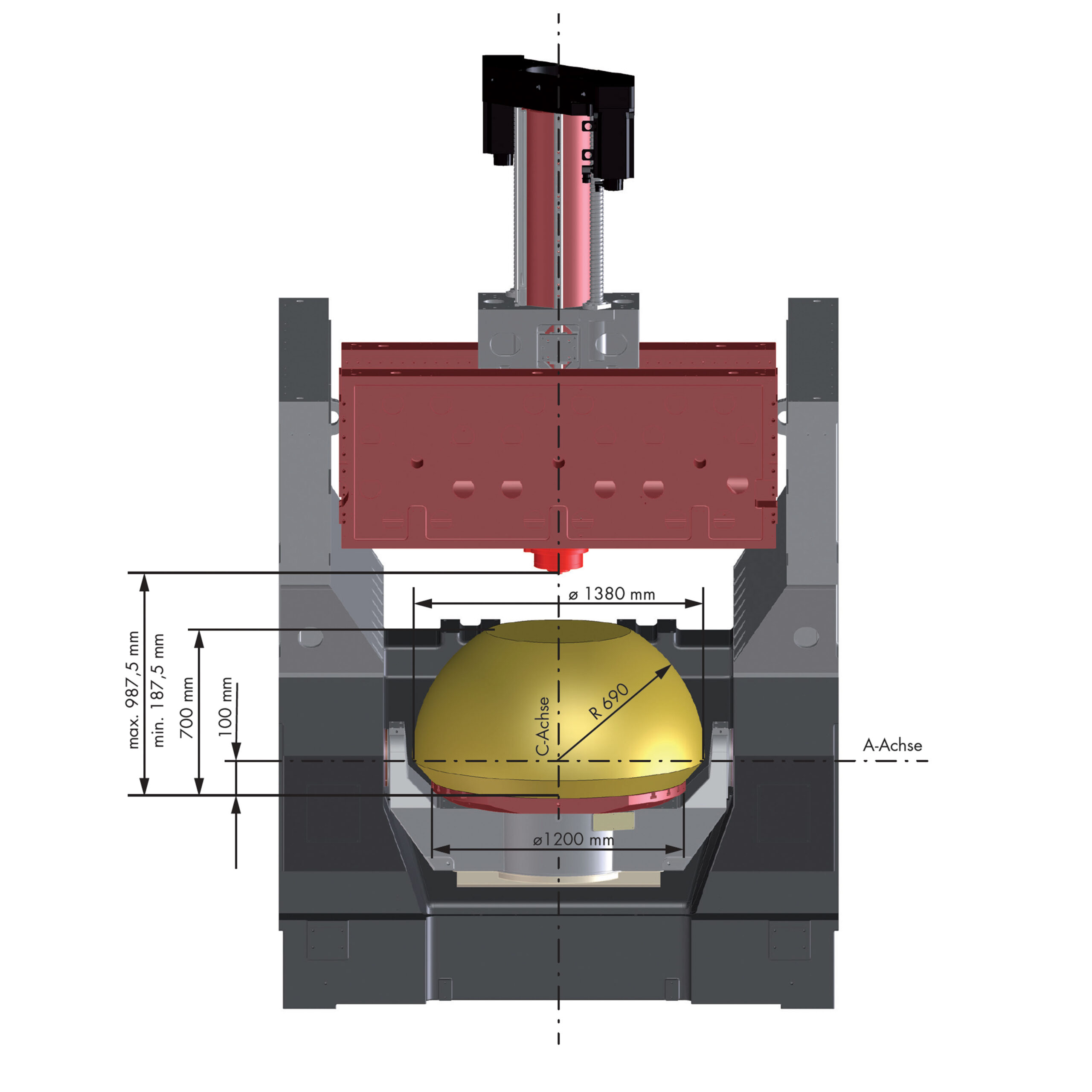

| Interference circle diameter | |

| Distance Spindle | |

| Machine-Table Load | |

| Maximum rapid travel X/Y/Z at TCP max. | |

| Cutting-Tool Interface | |

| Motor-Spindle-Power at CDF 25% max. | |

| Motor-Spindle Torque at CDF 25% max. |

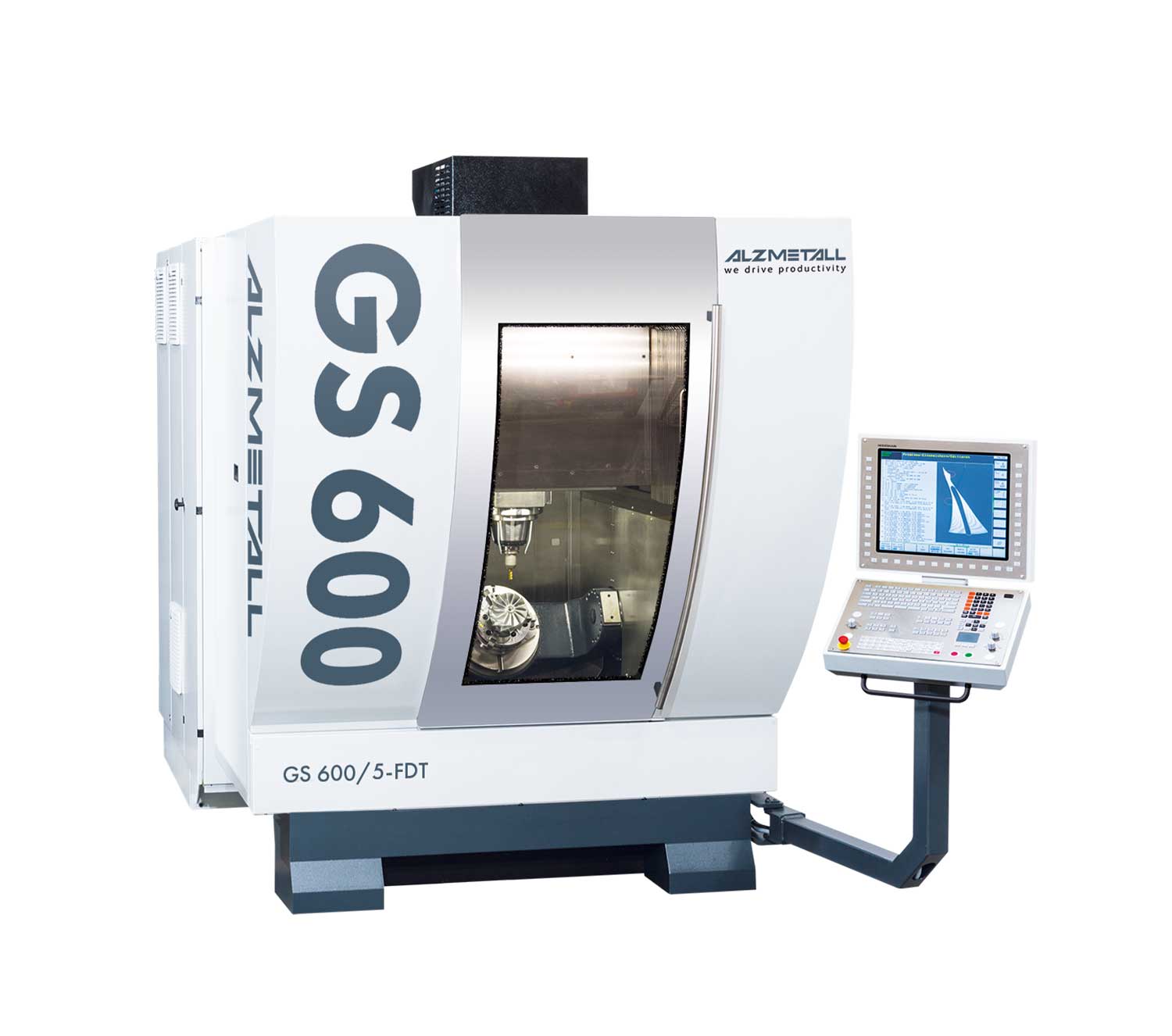

GS 1400/5-T

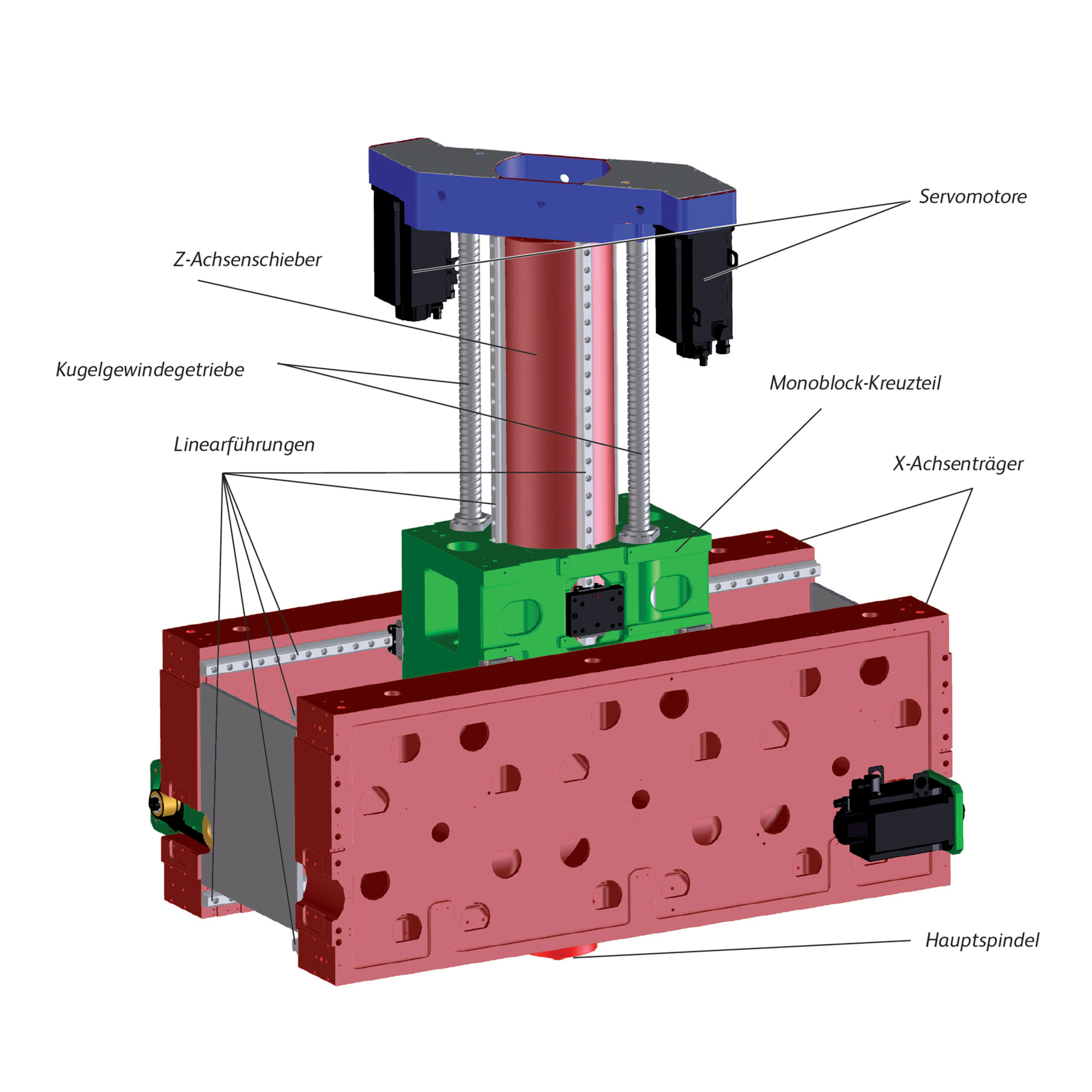

ALZMETALL-Gantry-Conzept (AGK)

- Grey Cast Iron and Spheroidal Graphite Cast Iron Machine Body and Frame components

- Travel-System-Carriage with incorporated Box-in-Box-System – patented –

- 4-fold Linear Guidance for Travel-System-Carriage and Z-Axis with integrated Motor-Spindle

- 3-fold Torque-Drives for Swivel-Axis (A-Axis) and Rotary-Axis (C-Axis)

- Hybrid-Machining-Applications such as: Drilling/Milling/Turning and Grinding at one Clamping-Set-Up

- Up to 3000 kg workpiece weight including Clamping-Set-Up-Device

- NC - Swivel - (A-Axis) and Rotary-Tables (C-Axis): Table-Set: Rotary-Table C-Axis, Rotary-Table C-Axis with NPS

- CNC-Controls - Heidenhain TNC 640 (Standard)

- CNC-Controls Siemens SINUMERIK 840 D sl

- KINEMATIK Gauging

- Electrical Handwheels

- 3D -Touch Probes Infrared transmission

- Multiple-Media-Coupling

- Tool Setting System

- Camera and Screen

- Tool-Magazines: Twin magazine: up to 150 Tool positions, (Chain Magazine)

- Tool-Magazines: Rack-Type Magazines designed for 250 Tool Positions

- Operating Supply Unit Set‘s: Bundle set‘s A, B, C cooling and cleaning circuit system up to 80 bar high pressure, on selection Scratch-Type or Hinge-Type-Conveyor

- Operating Supply Unit Set‘s: Coolant Cleaning Unit with Compact-Paper-Filter

- Mist Extraction Unit

- Remote Diagnosis and Maintenance

- Machining Center Acceptance: Workpiece according to ALZMETALL-Standard, on selection Customer-Workpiece (option)

- Services: NC-Program-Training, Operator-Training for Heidenhain and Siemens and Machining Center Installation and Commissioning, Process development, Production Assistance, Service and Maintenance

- More Services: Cutting-Tool Setting and Detection, Mist Extraction Units, Equipment for Graphite Machining, Custom-Made Solutions

REQUEST PRODUCT

PRODUCT CATALOG

Find out more about our machining centers by downloading our product catalogs.